ChemTreatEDS ™

Home > BioWaste Effluent Decontamination Systems > ChemTreatEDS ™

Introduction to ChemTreatEDS ™ BioWaste Decontamination Kill Chemical System

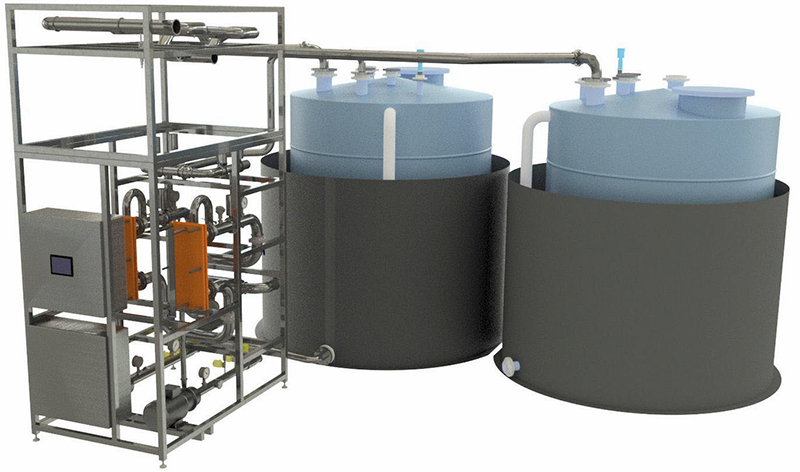

Suncombe ChemTreatEDS ™ BioWaste Decontamination Kill Chemical Systems are used for the chemical treatment of effluent and waste generated by research, laboratory, production and bio-containment facilities from a single laboratory room to a large multi-user facility and for production and process waste decontamination.

The Suncombe ChemTreatEDS ™ BioWaste Decontamination Kill Chemical System is a heavy duty validateable Batch BioWaste Decontamination System used for Biological Hazardous Effluent Decontamination and Growth Media Sterilisation for CL levels 2 and 3.

Available in a wide range of capacities and configurations, ChemTreatEDS ™ systems are available for treating waste from any size facility from a single laboratory room to a large multi-user facility and for production and process waste decontamination.

Crafted to a standardised blueprint yet adaptable to tailor-fit client needs, these effluent decontamination systems excel in hazardous waste treatment by employing cutting-edge instrumentation, precise chemical blending, and flexible control mechanisms to accomplish thorough decontamination.

ChemTreatEDS ™ Datasheet

Features

- Positive release of waste post treatment

- Minimisation of direct energy and utility usage

- Duty/standby arrangement in case of equipment failure providing guaranteed availability

- Developed and manufactured in the United Kingdom

- Designed for reliable, efficiency and validatable performance

- Tanks incorporating self bundss

- High quality HDPE Tanks with options for 316 stainless steel, duplex steel and other thermoplastics

- Stainless steel framework and control panels

- 316 stainless steel pipework with options for duplex steel or thermoplastics pipework

- Optional safety Interlocks to SIL3

- Pressure relief and safety devices

- Risk assessment, method statements, operating instructions and full documentation

- 2D drawings and 3D models

- Factory Acceptance Testing Included

- Local control location with remote control locations available

- Optional interfaces to waste generation equipment, DCS, BMS, Historian etc.

- Options for cooling systems to control the temperature of the outgoing effluent

- Full wet Factory Acceptance Test with all equipment

- Full safety features to ensure no effluent discharge in the event of out of condition discharge or failure

- Local and remote Alarm messages